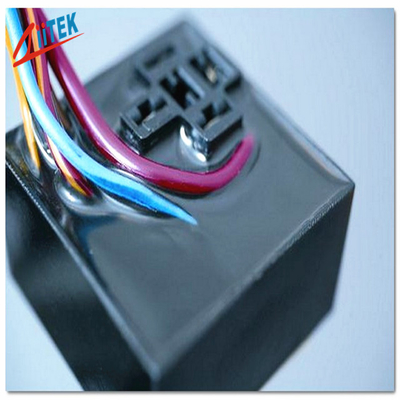

Two-Component High Thermal Conductivity Epoxy Resin Glue Compound For Electronic Components Encapsulation

TIETM280-12AB Series is a two-component, high thermal conductive, low temperature cured, long pot life, fire resistant Silica encapsulant glue. lt is design for potting of capacitors and electrical devices.Their flexibility and elasticity make them suited to the coating of the very uneven surfaces.Heat can transmit to the metal housing or dissipation plate from the separate elements or even the entire PCB, which in effect enhances the efficiency and life-time of the heat-generating electronic components.

TIE280-12AB-Series-Datasheet (2).pdf

Features

> Good thermal conductive: 1.2W/mK

> Excellent insulation and smoothly sourface.

> Low shrinkage

> Low viscosity, expediting air releaseed.

> Excellent in solvents and water proof.

> Longer life time.

> Excellent thermal shock efficiecy and impact resistance

Application

>To potting LED Lighting heat spreader and power- driver.

>Ferrite cements; tip type LED; good cementation to aromatic polyester

>Relay sealant; Good adhesion to rubber, ceramics,PCB and plastics

>Power transformers and coils; Potting capacitors; Potting of small electrical devices

>Adhesion to metal glass and plastic;LCD & substrates adhesion; Coating and sealant; Coil ; IGBTS;Transformer; Fire retardant

>Optical / medical component adhesive

| Typical Properties of TIETM280-12AB Series |

| Typical Uncured Material |

| TIETM280-12A(Resin) |

Mixing ratio (weight ratio)

A:=1 :1 |

| Color |

Black |

| Viscosity @25℃ Brookfield |

15000 cPs |

Viscosity @25℃ Brookfield |

10000 cPs |

| Operating time (@25℃) |

45 mins |

| Shelf life @25℃ in sealed |

12 months |

specific Gravity |

1.6 g/cc |

| Mixture Color |

Black |

| TIE280-12B(Hardener) |

Cure Schedule |

| Color |

Black |

Cure at 25C |

3 hrs |

| Viscosity @25℃ Brookfield |

7000 cPs |

| Shelf life @25℃ in sealed container |

12 months |

Cure at 7o°c |

30 mins |

| Cured Properties |

| Hardness @25℃ |

85 Shore D |

| Operating temperature |

-40℃ ~160℃ |

| Glass transition temperature Tg |

92℃ |

| Rate of tension |

0.10% |

| Coefficient of thermal expansion, /℃ |

3.0x 10^(-5) |

| Fire resistance UL |

94 V-0 |

| Moisture absorption % wt gain 24 hours water immersion @25℃ |

<0.1% |

| Thermal Conductivity |

1.2 W/m-K |

| Dielectric Breakdown Voltage |

300 volts / mil |

| Dielectric Constant@1MHz |

4.2 |

| volume resistivity, ohm-cm @ 25℃ |

3.0x 10^13 |

Product packaging:

1KG A/B for each tank.

5KG A/B each.

10KG A/B each.

Company profile

Ziitek company is a high-tech enterprise which dedicated to the R&D, manufacture and sales of the thermal interface materials (TIMs). We have rich experiences in this field which can support you the latest, most effective and one -step thermal management solutions. We have many advanced production equipments,full test equipments and fully automatic coating production lines which can support the production for high performance thermal silicone pad, thermal graphite sheet/ film, thermal double-sided tape, thermal insulation pad, thermal ceramic pad, phase change material, thermal grease etc. UL94 V-0, SGS and ROHS are compliant.

Ziitek Culture

Quality :

Do it right the first time, total quality control

Effectiveness:

Work precisely and thoroughly for effectiveness

Service:

Quick response, On time delivery and Excellent service

Team work:

Complete teamwork, including sales team, Marketing team, engineering team, R&D team, Manufacturing team, logistics team. All is for supporting and servicing a satisfy service for customers.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!