Company Profile

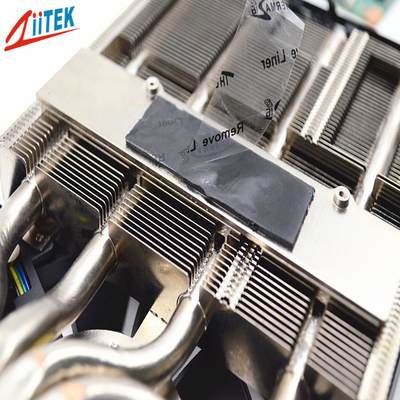

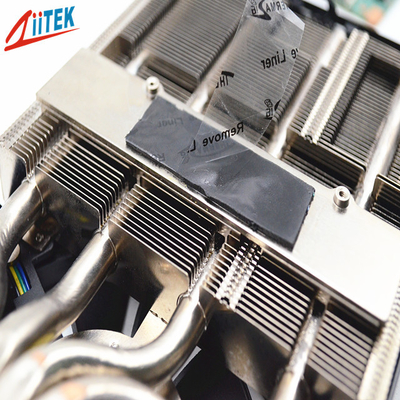

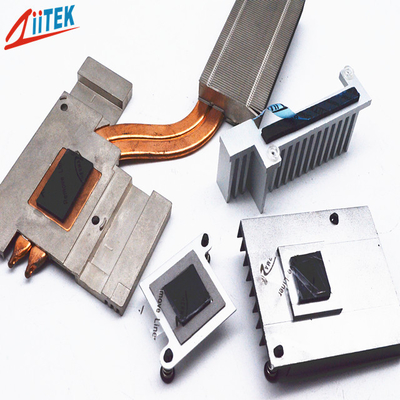

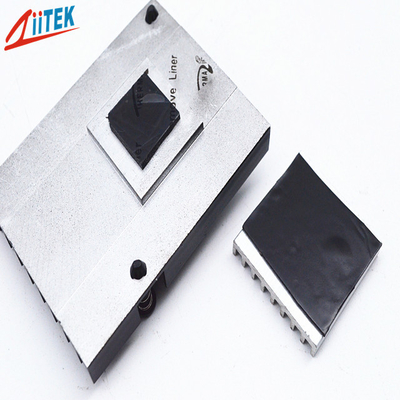

With a wide range, good quality, reasonable prices and stylish designs, Ziitek thermal conductive interface materials are extensively used in Mainboards, VGA cards, Notebooks, DDR&DDR2 products, CD-ROM ,LCD TV, PDP products, Server Power products, Down lamps, Spotlights, Street lamps, Daylight lamps, LED Server Power products and others.

Packaging Details & Lead time

The packaging of thermal pad

1.with PET film or foam-for protection

2. use Paper Card To Separate Each Layer

3. export carton inside and outside

4. meet with customers' requirement-customized

Lead Time :Quantity(Pieces):5000

Est. Time(days): To be negotiated

6.Quality assurance contract

Standard Thicknesses:

0.020" (0.51mm) 0.030" (0.76mm)

0.040" (1.02mm) 0.050" (1.27mm) 0.060" (1.52mm)

0.070" (1.78mm) 0.080" (2.03mm) 0.090" (2.29mm)

0.100" (2.54mm) 0.110" (2.79mm) 0.120" (3.05mm)

0.130" (3.30mm) 0.140" (3.56mm) 0.150" (3.81mm)

0.160" (4.06mm) 0.170" (4.32mm) 0.180" (4.57mm)

0.190" (4.83mm) 0.200" (5.08mm)

Consult the factory to alternate thickness.

FAQ

Q: Do you offer free samples ?

A: Yes, we are willing to offer free sample.

Q: What's the thermal conductivity test method given on the data sheet ?

A: All the data in the sheet are actual tested.Hot Disk and ASTM D5470 are utilized to test the thermal conductivity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!