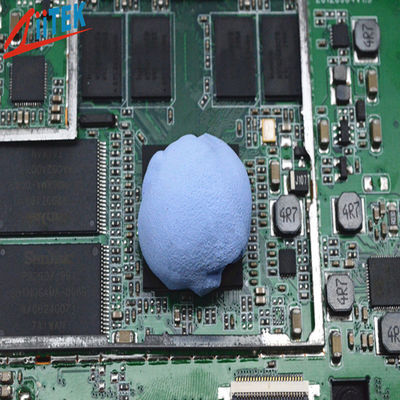

TIF®030-05 is a soft silicone gel-based gap filer pad, formulated with a special blend of filers to provide both excellent thermal conductivity and superior softness. Compared to conventional thermal greases, TIF®030-05 has a higher viscosity, which effectively prevents filler separation from the silicone matrix and reduces filler migration, helping maintain consistent thermal performance. It is applied in a similar manner to thermal grease and is suitable for commercial dispensing or automated equipment. Typical applications include flip-chip microprocessors, PPGAs, micro BGA packages, BGA packages, DSP chips, circular Isilicon chips, LED lighting, and other high-power electronic components.

Feature

>Thermal conductivity: 3.0 W/mK

>Soft, very low compression

>Low thermal impedance

>Operate automatically

>Proven long-term reliability

Application

>Heat-sink & frame

>LED backlight module,LED lighting

>High speed hardware driver

>Micro heat pipe

>Vihicel enginee controller

>Telecom industry

>Semiconductor automatic laboratory equipment

| TIF®030-05 Typical Properties |

| Property |

Value |

Test method |

| Color |

Blue |

Visual |

| Construction & Composition |

Ceramic filled silicon material |

- |

| Flow Rate(g/min) |

30 |

Ziitek Test Method (30 cc syringe/ 2.5 mm orifice/ 90 psi) |

| Density(g/cc) |

3.25g/c |

ASTM D297 |

| Thermal conductivity |

3.0W/mK |

ASTM D5470 |

| Thermal Impedance @10psi (℃.in²w) |

0.08 |

ASTM D5470 |

| Thermal Impedance @50psi (℃.in²w) |

0.075 |

ASTM D5470 |

| Recommended Operating Temp |

-45 ~200°C |

Ziitek Test Method |

| Dielectric Strength(V/mm) |

≥4000 |

ASTM D149 |

| Bond Line Thickness(mm) |

0.1 |

Ziitek Test Mothod |

| Flame Rating |

V-0 |

UL 94 |

| Shelf Life |

12 months |

- |

Product Specification:

30 cc/pcs, 98 pcs/box; 300 cc/pcs, 6 pcs/box.

Custom packaging available for automation use. Please contact us for confirming.

If you want to know our thermal products, please visit our website.

Company Profile

Dongguan Ziitek Electronic Material Technology Co., Ltd. was established in 2006. Is a high-tech enterprise specializing in the research, development, production and sales of thermal interface materials. We mainly produce: heat-conducting joint filler, low melting point thermal interface materials, heat-conducting insulator, heat-conducting adhesive tape, heat-conducting interface pad and heat-conducting grease, heat-conducting plastic, silicone rubber, silicone rubber foam, etc. We adhere to the business philosophy of "survival by quality, development by quality", and continue to provide the most efficient and best service for new and old customers with excellent quality in the spirit of rigor, pragmatism and innovation.

FAQ:

Q: How do I place an order?

A:1. Click the "Sent messages" button to continue with the process.

2. Fill out the message form by entering a subject line, and message to us.

This message should include any questions you might have about the products as well as your purchase requests.

3. Click the "Send" button when you are finished to complete the process and send your message to us

4. We will reply you as soon as possible with Email or online

Q: How do I request customized samples?

A: To request samples, you can leave us message on website, or just contact us by send email or call us.

Q: What's the thermal conductivity test method given on the data sheet ?

A: All the data in the sheet are actual tested.Hot Disk and ASTM D5470 are utilized to test the thermal conductivity.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!