UL And RoHs Certificated High Thermal Conductivity 2.6W Thermal Conductive Pad For Unmanned Aerial Vehicle (UAV)

Products description

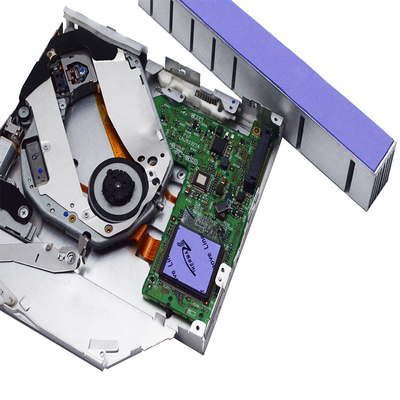

The TIF®500US thermally conductive interface materials are applied to fill the air gaps between the heating elements and the heat dissipation fins or the metal base. Their flexibility and elasticity make them suited to the coating of the very uneven surfaces. Heat can transmit to the metal housing or dissipation plate from the separate elements or even the entire PCB, which in effect enhances the efficiency and life-time of the heat-generating electronic components.

Features:

> Good thermal conductive: 2.6 W/mK

> Naturally tacky needing no further adhesive coating

> Soft and Compressible for low stress applications

> Available in varies thickness

Applications:

> Cooling components to the chassis of frame

> High speed mass storage drives

> Heat Sinking Housing at LED-lit BLU in LCD

> LED TV and LED-lit lamps

> RDRAM memory modules

> Micro heat pipe thermal solutions

> Automotive engine control units

> Telecommunication hardware

> Routers

> Medical Devices

> Auditioning electronic products

> unmanned aerial vehicle(UAV)

|

Typical Properties of TIF®500US Series

|

|

Color

|

Violet

|

Visual |

|

Construction & Compostion

|

Ceramic filled silicone elastomer

|

****** |

|

Specific Gravity

|

2.95 g/cc |

ASTM D297 |

| Thickness range |

0.020"(0.500)~0.200"(5.0mm) |

ASTM D374 |

|

Hardness

|

18 Shore 00

|

ASTM 2240 |

| Operating temp |

-45 to 200℃ |

******

|

|

Dielectric Breakdown Voltage

|

>5500 VAC |

ASTM D149 |

|

Dielectric Constant @1MHz

|

4.3 |

ASTM D150 |

|

Volume Resistivity

|

>4.2X1013 Ohm-meter |

ASTM D257 |

|

Flame rating

|

94 V0 |

UL E331100

|

| Outgassing (TML) |

0.55% |

ASTM E595 |

|

Thermal conductivity

|

2.6 W/m-K

|

ASTM D5470 |

Products specification

Product Thicknesses: 0.020-inch to 0.200-inch (0.5mm to 5.0mm)

Product Sizes: 8" x 16"(203mm x406mm)

Individua de cut shapes and custom thickness can be supplied. Please contact us for confirming

Peressure Sensitive Adhesive:

Request adhesive on one side with "A1" suffix.

Request adhesive on double side with "A2" suffix.

Reinforcement:

TIF series sheets type can add with fiberglass reinforced.

Ziitek Culture

Quality :

Do it right the first time, total quality control

Effectiveness:

Work precisely and thoroughly for effectiveness

Service:

Quick response, On time delivery and Excellent service

Team work:

Complete teamwork, including sales team, Marketing team, engineering team, R&D team, Manufacturing team, logistics team. All is for supporting and servicing a satisfy service for customers.

Our services

Online-service : 12 hours , Inquiry reply within fastest.

Working time: 8:00am - 5:30pm, Monday to Saturday (UTC+8).

Well-trained & experienced staff are to answer all your inquiries in English of course.

Standard Export Carton Or Marked With Customer's Information Or Customized.

Provide free samples

After-service: Even our products have passed strict inspection, if you find the parts can not work well, please show us the proof.

we will help you to deal with it and give you satisfactory solution.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!